Assessing the Environmental Impact of a 10% Reduction in Powder Usage in the Global Powder Coating Industry

The powder coating industry is a multibillion-dollar global enterprise with diverse applications spanning manufacturing, construction, and consumer goods. Industry reports estimate that over 2 million metric tons of powder are produced annually, meaning that a 10% reduction in powder usage globally would result in 200 thousand metric tons of powder coating saved-which in turn would greatly reduce the CO₂ footprint of the entire industry. Through Blueprint™ OS, coatingAI guarantees a minimum of 10% in powder savings.

Global Powder Coating Industry Overview

The global powder coatings market has experienced significant growth over the past few decades. In 2022, the market generated a revenue of approximately USD 34.36 billion and is projected to reach USD 50.73 billion by 2030, growing at a compound annual growth rate (CAGR) of 5%.

According to Grand View Research, this growth is driven by increasing demand from various sectors:

- Automotive Industry: Powder coatings are extensively used for coating automotive parts due to their superior durability and resistance to corrosion. The automotive segment is among the fastest-growing applications in the powder coating market.

- Appliances: The appliance segment is expected to be a leading application area, driven by the need for durable and aesthetically appealing finishes on household and industrial appliances.

- Architectural Sector: The demand for powder coatings in architectural applications is fueled by their environmental benefits and the increasing focus on sustainable building practices.

- Furniture Industry: Furniture manufacturers are also transitioning to low-cure powder systems that significantly reduce energy consumption during curing processes while maintaining high-quality finishes.

Environmental Impact of Powder Coating

Powder coatings are recognized for their environmentally friendly properties compared to traditional solvent-based coatings, however, the industry still has a significant environmental impact. The powder coating industry accounts for anywhere between 3 million to 5 million metric tons of CO₂ annually. Key environmental advantages of powder coatings, as opposed to solvent-based coatings include:

- Reduced Volatile Organic Compounds (VOCs): According to the Powder Coating Institute, powder coatings contain no solvents and therefore emit negligible, if any, polluting VOCs into the atmosphere.

- Lower Carbon Footprint: Studies have shown that powder coatings can reduce CO₂ emissions by 25–60% compared to conventional solvent-borne coating systems.

The Promise of a 10% Reduction in Powder Usage

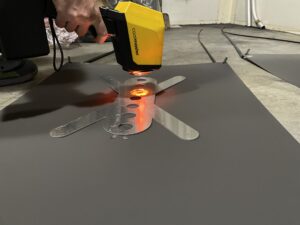

Imagine the potential if technology enabled a 10% reduction in powder usage across industries. At coatingAI we guarantee a 10% reduction in powder usage through the implementation of our Blueprint™ OS. While this may seem modest, the potential impact on sustainability and costs is transformative:

Material Conservation

A 10% reduction could save 200,000 metric tons of powder annually, decreasing the demand for raw materials and mitigating the environmental toll of extraction and processing.

Energy Savings

Using less powder means less energy required for production and curing. This could save approximately 300,000 to 500,000 tons of CO₂ annually, equivalent to removing 65,000 to 100,000 passenger cars from the road.

Waste Reduction

More efficient application processes would result in reduced overspray, less material waste, and lower disposal costs, lightening the burden on landfills and waste management systems.

Economic Benefits

Lower raw material and energy costs could translate to savings for manufacturers, potentially reducing prices for consumers while improving profit margins.

Industry Impacts

Leading companies like Akzo Nobel N.V., PPG Industries, Inc., and Sherwin-Williams Company are at the forefront of powder coating innovation. These industry giants invest in research and new technologies to improve efficiency, reduce environmental impact, and comply with increasingly stringent sustainability regulations.

Automotive Sector

With powder coatings extensively used for parts like wheels and chassis, a 10% reduction in usage could significantly reduce costs and emissions, setting a precedent for other industries.

Appliances and Consumer Goods

Energy-efficient and waste-minimizing practices in appliance manufacturing could align with consumer demand for eco-friendly products.

Architectural Applications

Sustainability is paramount in construction, and improved powder coating technology could enhance green building certifications like LEED.

Aligning with Global Sustainability Goals

Reducing powder usage directly supports global sustainability objectives, including the United Nations Sustainable Development Goals (SDGs):

- Goal 12: Responsible Consumption and Production: Reducing resource use and waste aligns with promoting sustainable industrial practices.

- Goal 13: Climate Action: Cutting CO₂ emissions contributes to global efforts to mitigate climate change.

Furthermore, advancements in powder coating technology could catalyze innovation in other industrial processes, inspiring broader adoption of sustainable practices.

A Step Towards a Greener Planet with coatingAI

Reducing powder usage by 10% may appear incremental, but its ripple effects are profound. The environmental benefits, ranging from lower CO₂ emissions and energy savings to reduce waste, complement the economic advantages for businesses and consumers. As industries strive to balance performance and sustainability, embracing innovations in powder coating is a clear step toward a greener, more responsible future.

By prioritizing resource efficiency and sustainability, the powder coating industry can lead by example, showing that small changes can drive significant progress in combating climate change and reducing oir environmental footprint.