Optimizing your coating line is critical for achieving higher efficiency, improved product quality, and reduced operational costs. At coatingAI, we strive to maximize the efficiency of coating lines with modern technologies, leveraging AI to streamline the coating process.

Running a coating line without proper optimization can be costly, inefficient, and unsustainable. At coatingAI, we understand these challenges, which is why we’ve developed Blueprint™ OS, a system designed to simplify implementation, reduce waste, and guarantee a return on investment within days. Blueprint™ OS is our answer to the question “how to optimize a coating line”, transforming your coating process into a high-efficiency operation with precision and ease.

Why Coating Line Optimization is Critical

Coating lines play a vital role in manufacturing, but inefficiencies can lead to significant powder waste, uneven coatings, and costly downtime. Common challenges include:

- Inefficient manual adjustments.

- Guesswork in setting spray patterns or reciprocator movements.

- Downtime caused by equipment wear and tear.

Blueprint™ OS addresses these issues by providing precise, data-driven insights and automated adjustments, ensuring consistent, high-quality coatings.

How Blueprint™ OS Simplifies Optimization

Easy Setup for Instant Results

Unlike traditional optimization methods that require lengthy setups, Blueprint™ OS is designed for simple implementation with minimal disruption to your production.

- Quick Setup: Start seeing results within days of installation.

- Seamless Integration: Works with your existing equipment.

Guaranteed Savings and ROI

- 10% Powder Savings: Automated adjustments ensure optimal powder usage.

- Fast ROI: Clients typically see returns within days thanks to reduced waste and improved efficiency.

Features of Blueprint™ OS

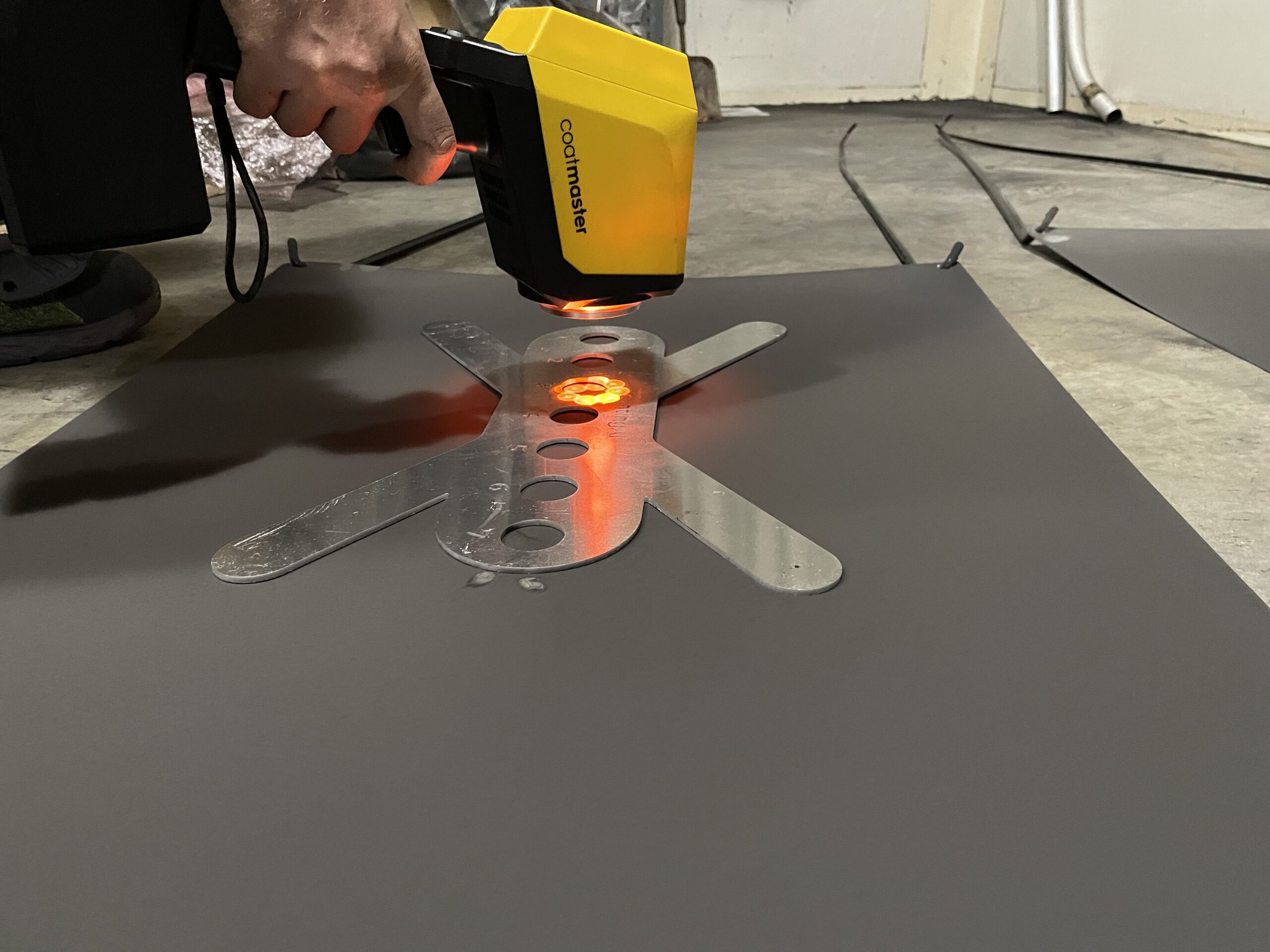

HealthCheck for Your Coating System

Stay ahead of issues with regular system health checks.

- Assess wear and tear on components in just 10 minutes.

- Identify and resolve potential problems before they disrupt production.

Replaces:

Trial-and-error troubleshooting and reliance on tribal knowledge.

Powder Equalization Tool

Achieve uniform powder distribution for consistent coatings.

- Equalize gun outputs with precision.

- Detect and correct discrepancies in spray patterns instantly.

Replaces:

Manual adjustments and powder wastage.

Spray Calibration System

Ensure optimal settings for each powder type.

- Tailor spray patterns and reciprocator settings for every powder.

- Eliminate striping and uneven coatings.

Replaces:

Inconsistent settings and time-consuming manual calibration.

Closed Loop Optimization

Automate real-time adjustments to maintain peak efficiency.

- Monitor and fine-tune coating thickness automatically.

- Guarantee consistent, uniform results for every batch.

Replaces:

Frequent manual tweaks and inefficient powder usage.

Fine-Tuning Module

Keep your line performing at its best with regular, quick adjustments.

- Perform weekly checks in under 15 minutes.

- Minimize downtime while maximizing performance.

Replaces:

Frequent interruptions and process inefficiencies.

Predictive Maintenance Solution

Prevent unexpected downtime by identifying issues before they occur.

- Track wear and tear on critical components.

- Receive early warnings about potential part failures.

Replaces:

Emergency part replacements and costly shutdowns.

Real Results from Blueprint™ OS

Blueprint™ OS is trusted by industry leaders like AkzoNobel, Surtech Industries, and Combined Finishing, Inc. Here’s what customers have to say:

“Blueprint™ OS has taken the guesswork out of the process, allowing coaters to focus on quality and efficiency. It’s become my go-to solution for clients looking to optimize their coating lines.”

— Jeff Cummins, Co-Founder, Combined Finishing, Inc.

“We’ve reduced human error and created a more consistent coating process. The software has allowed us to handle complex adjustments faster and better.”

— Achim Weiss, Operations Manager, MWN Pulverbeschichtungs GmbH

FAQs About Blueprint™ OS

How long does it take to see results?

You’ll experience measurable improvements within days, including up to 10% powder savings and reduced rejects.

Can Blueprint™ OS handle multiple powders and colors?

Yes, the system calibrates for your top-used powders and extrapolates settings for others, minimizing the need for recalibration during color changes.

What support does coatingAI provide?

We offer comprehensive post-implementation support, including ongoing fine-tuning, performance tracking, and predictive maintenance to keep your line running smoothly.

Get Started with Blueprint™ OS

We specialize in providing solutions for line manufacturers. With Blueprint™ OS, you can eliminate inefficiencies, reduce powder waste, and ensure flawless coatings with minimal effort.

Schedule a Free HealthCheck Consultation today and learn how your line can achieve:

- At least 10% powder savings.

- Improved coating quality.

- Increased production efficiency.